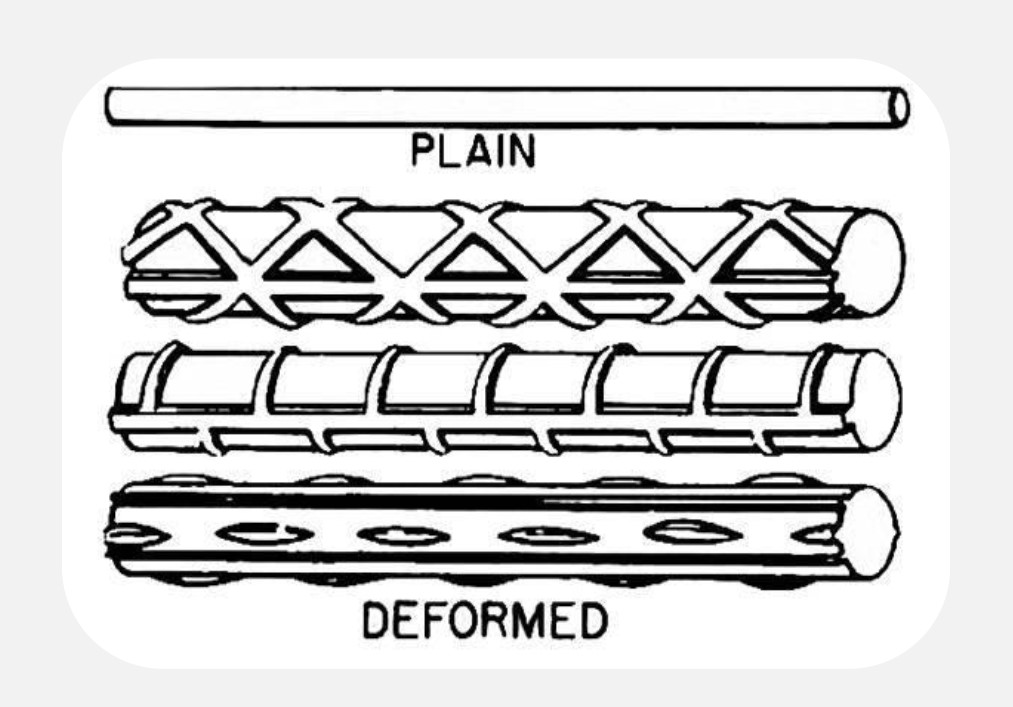

Deformed Bars Vs Plain Bars

Which is Better for Construction in Bangladesh?

Background

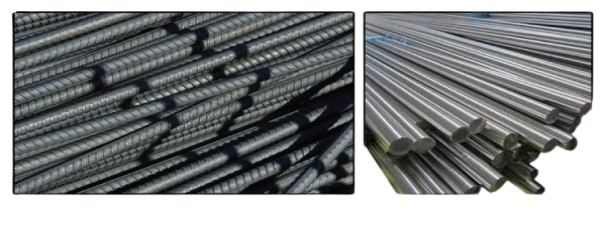

Understanding Deformed Bars

Benefits of Deformed Bars

Superior Bonding Strength: The ribs on deformed bars create a mechanical interlock with concrete, enhancing bonding strength. This feature is crucial in Bangladesh, where buildings must withstand

heavy rainfall and potential flooding.

Higher Load-Bearing Capacity: Deformed bars can support greater loads compared to plain bars due

to their superior tensile strength. This characteristic is vital for high-rise buildings and infrastructure

projects in urban areas like Dhaka, Chittagong, Sylhet, Rajshahi and Cox’s Bazar.

Crack Resistance and Ductility: The design of deformed bars allows them to absorb stress better,

reducing the likelihood of cracks under dynamic loads. This property is particularly beneficial in

earthquake-prone regions of Bangladesh.

Corrosion Resistance: Many Bangladeshi steel manufacturers produce deformed bars with corrosionresistant coatings, making them suitable for humid environments.

Versatility in Construction: Deformed bars are available in various sizes and grades, making them

adaptable for different construction needs, from residential buildings to large-scale infrastructure

projects.

Drawbacks

Costly

Complex Handling

Understanding Plain Bars

Benefits of Plain Bars

Ease of Use

Cost-Effective

Drawbacks

Lower Bond Strength: Plain bars do not bond effectively with concrete, leading to increased slippage

under load. This can compromise structural integrity over time.

Limited Applications: Due to their lower tensile strength, plain bars are mainly used in low-stress

applications such as non-structural elements or minor construction projects.

Cost-Effectiveness: While plain bars may be cheaper initially, their long-term performance issues can lead to higher maintenance costs.

Understanding Plain Bars

The Bangladeshi Steel Market Perspective