ELITE STEEL introduces German THERMEX QST TECHNOLOGY In Bangladesh Market

Introduction

In the world of construction, strength and durability are paramount. Elite Steel is proud to introduce

ELITE THERMEX, a revolutionary product engineered using German Thermex QST Technology, a

leader in thermoprocessed or quenching & self-tempering technologies. This advanced process sets a

new benchmark for rebar manufacturing, combining innovation, precision, and performance.

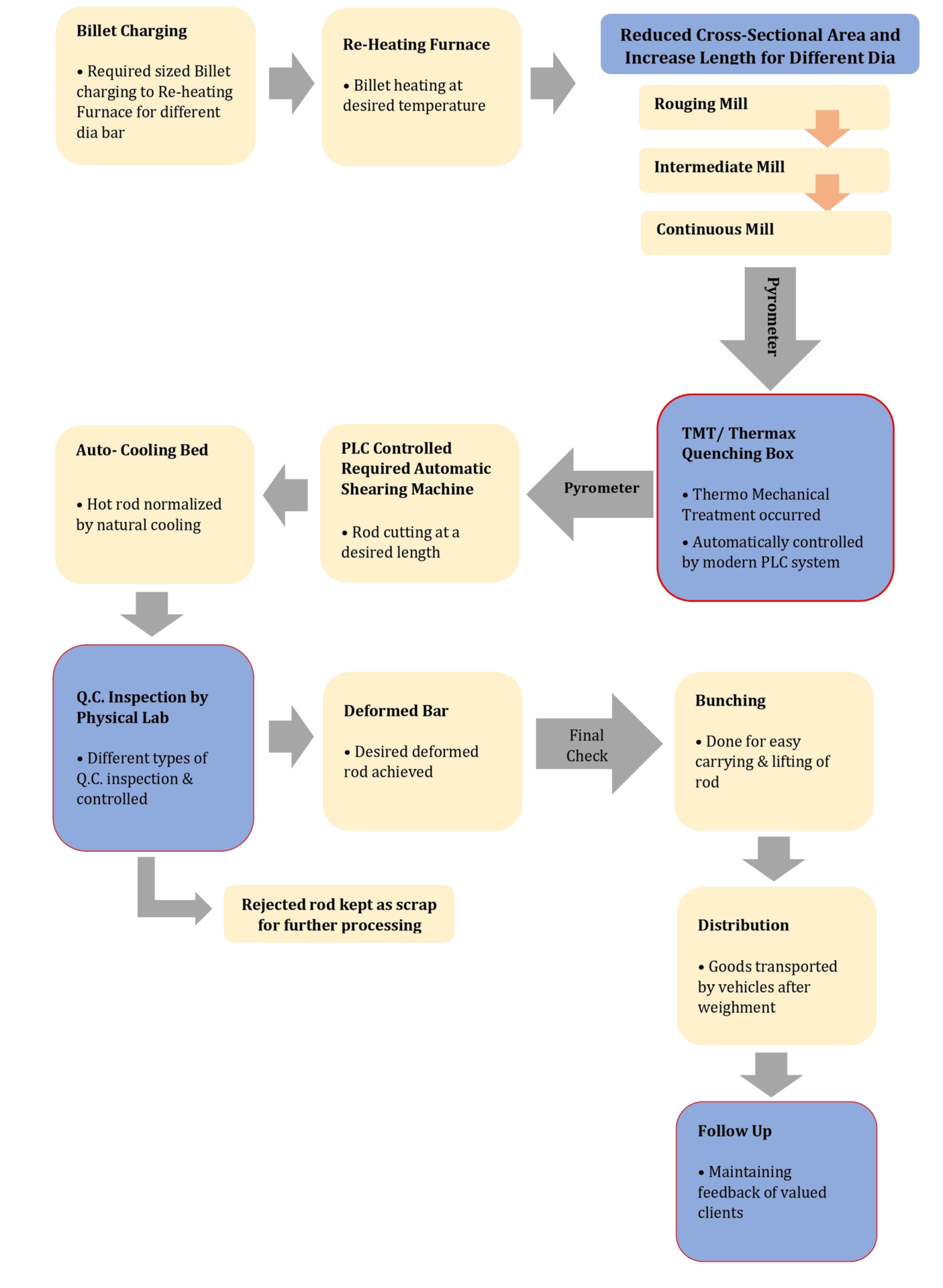

THERMEX QST TECHNOLOGY PROCESS

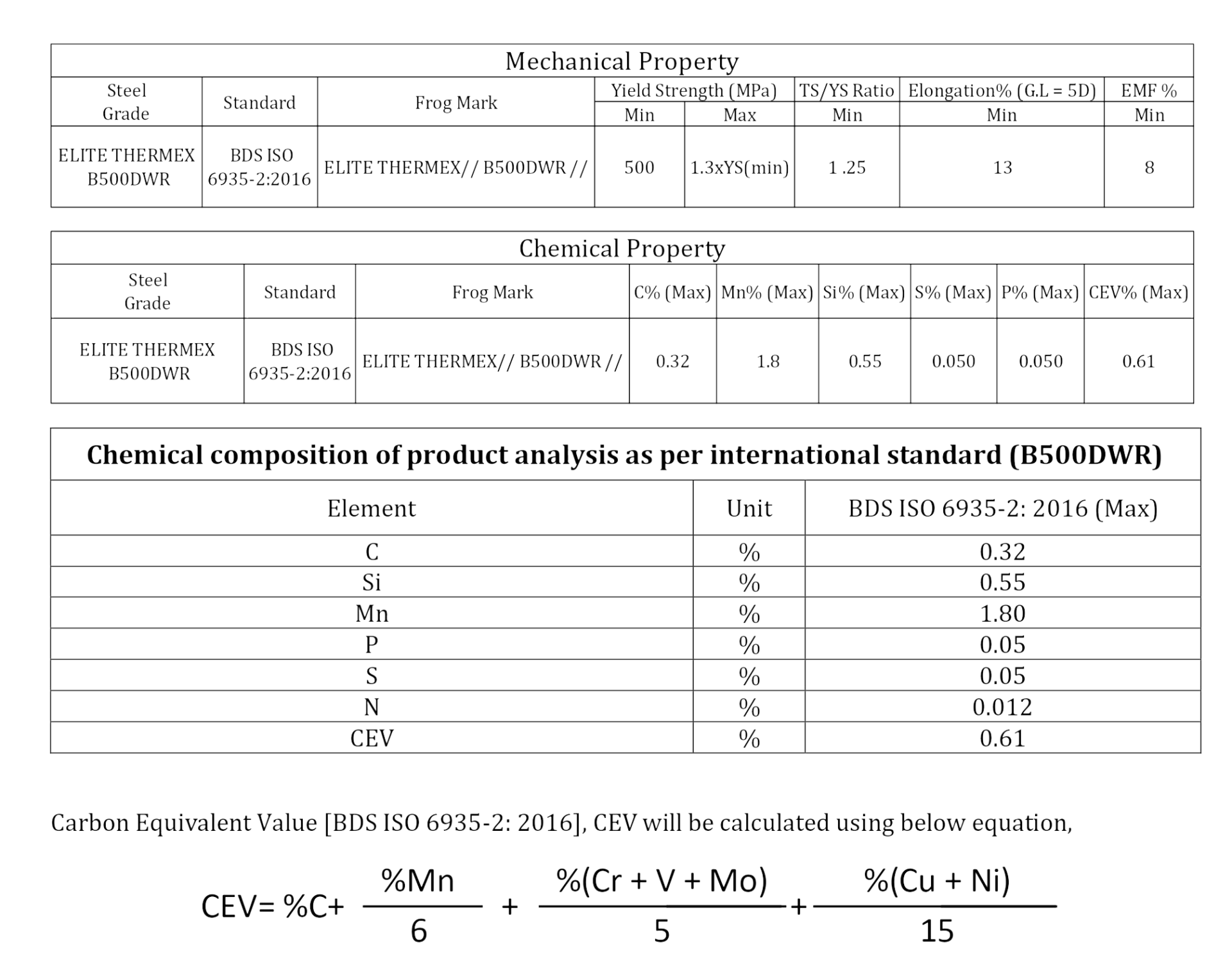

Thermex QST Technology is an advanced manufacturing process that ensures Grade B500DWR

rebars offer unmatched strength, flexibility, and corrosion resistance. It involves a series of meticulous

steps:

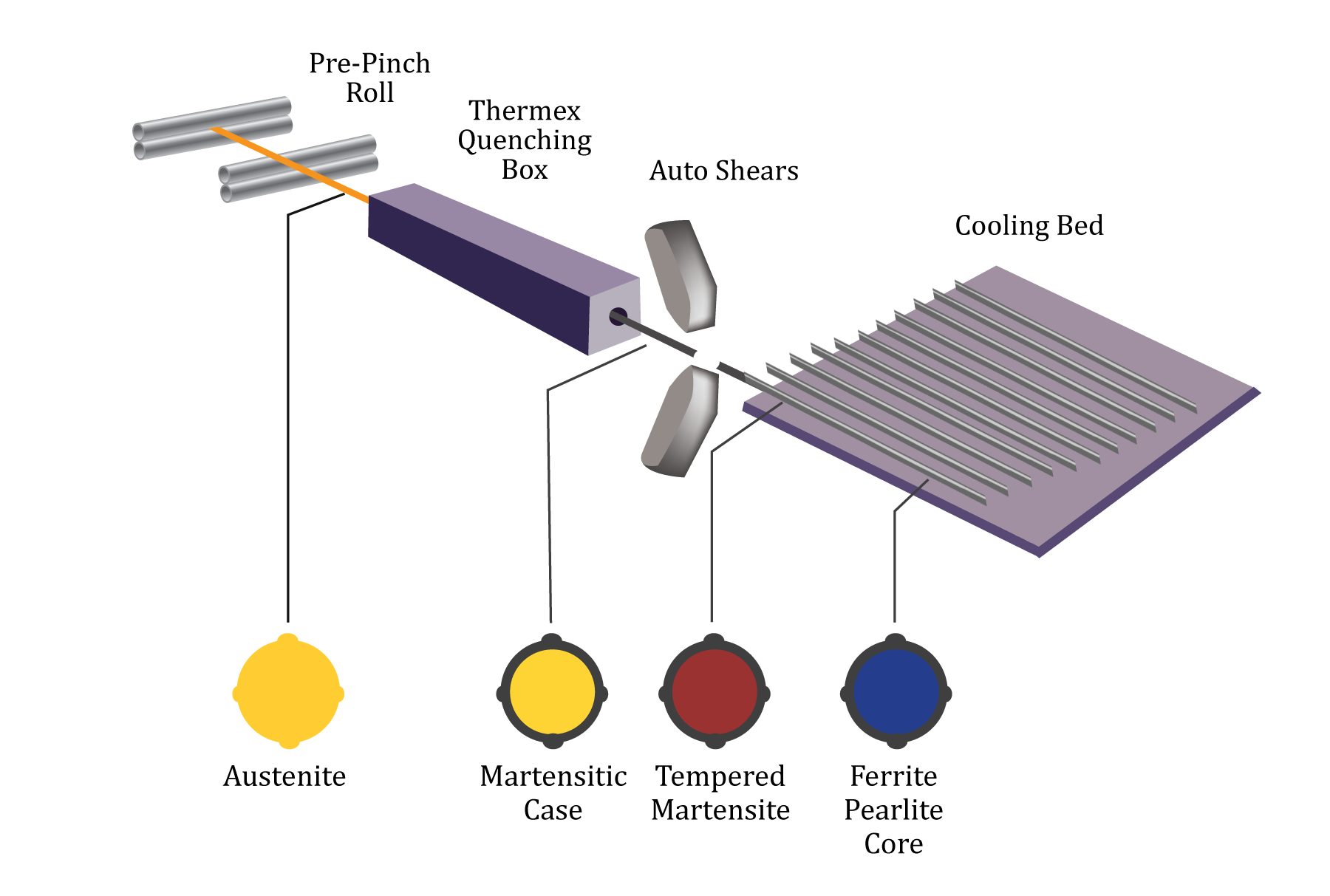

- Quenching: The last rolling station rapidly cools the hot bar using intense treated water pressure in specialized venturi tubes. This technique achieves an ideal depth of hardened exterior called Martensitic Case, creating an even Martensite Rings as boundary, while the core remains hot and austenitic.

- Self-Tempering: The bar exits the quenching tube remains hot at its core compared to the surface. This thermal gradient facilitates the transfer of heat from the core to the surface, resulting in the transformation of the outer martensitic layer into a desirable structure known as Tempered Martensite. The core of the bar remains austenitic throughout this process.

- Atmospheric Cooling: This final stage takes place on the cooling bed where the austenitic core undergoes a transformation into a ductile ferrite-pearlite structure. This process ensures that the final structure of Elite Steel rebars comprises a perfect balance between a durable outer layer (tempered martensite) and a flexible core (ferrite-pearlite). The resulting combination offers exceptional strength and ductile properties.

After cooling, the bars are cut and bundled into 12-meter length or in customized size through cold shearing.

Deformed Bars then stored in the Finished Goods-Yard categorized by Grade, Size, Lot Number, and other

relevant factors for dispatch.

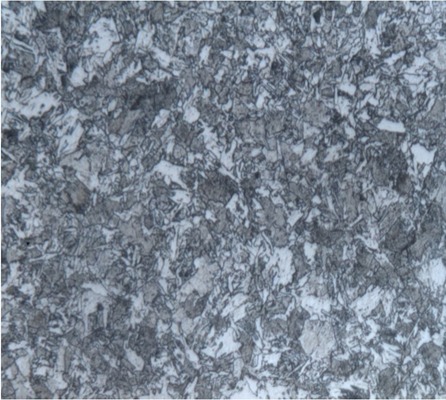

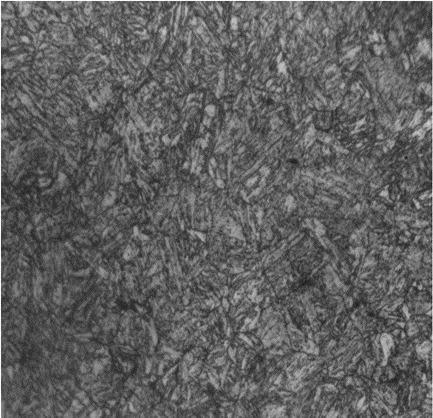

MARTENSITE RING & MICROSTRUCTURE OF DIFFERENT ZONE

1

A) Fine & Pearlite

B) Composite structure

C) Tempered Martensite

SALIENT FEATURES OF ELITE THERMEX B500DWR

Thermex QST Technology is an advanced manufacturing process that ensures Grade B500DWR

rebars offer unmatched strength, flexibility, and corrosion resistance. It involves a series of meticulous

steps:

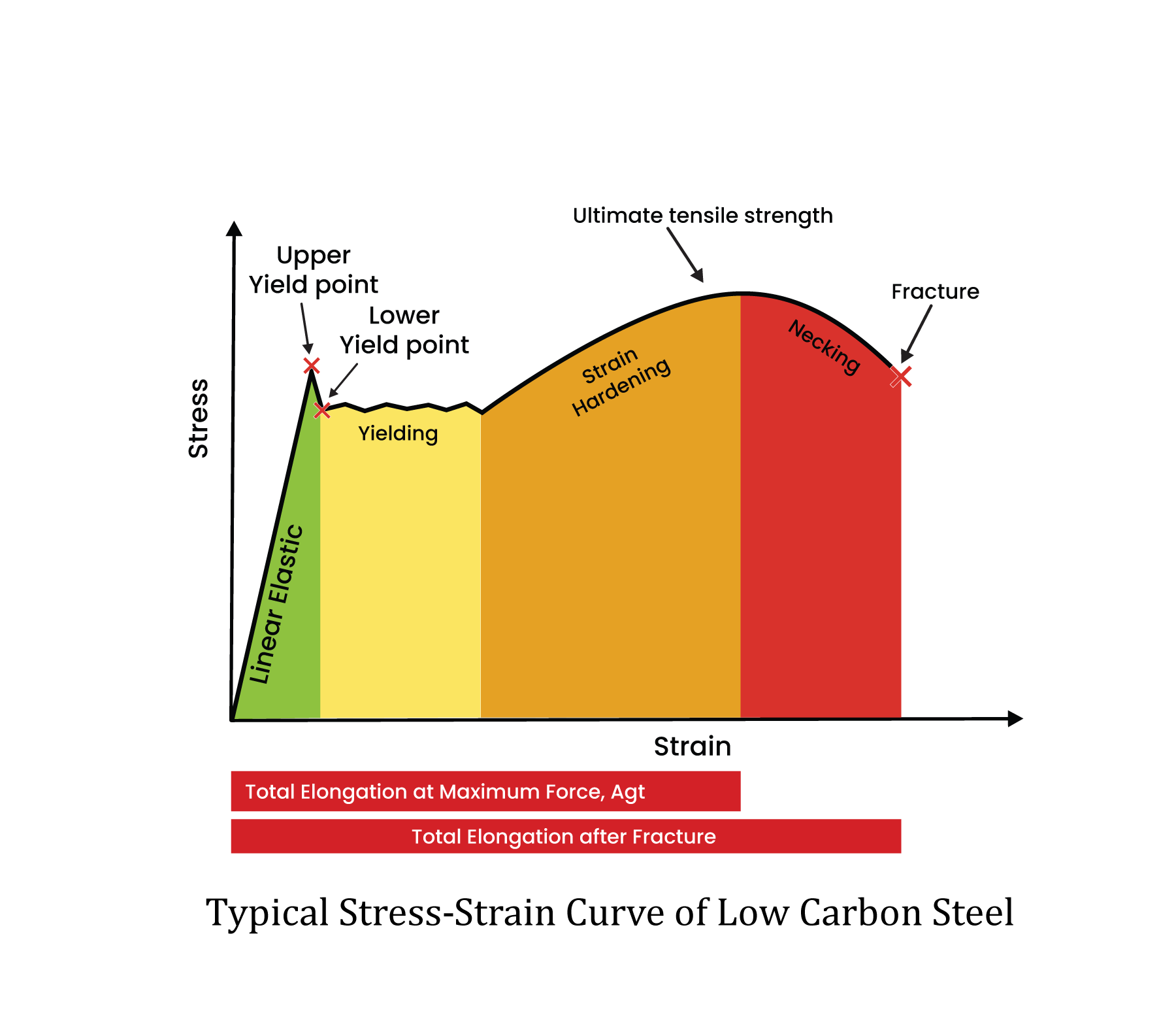

- Yield Strength : 500 MPa (Min) – 72,500 psi

- Ultimate (Tensile) Strength : 625 MPa (Min) – 90,625 psi

- Elongation : 8% min, according to BDS ISO 6935-2:2016

- De-scaled bars offer improved concrete bonding and reduced on-site wastage

- Physical properties and chemical composition are consistent

- Comparatively corrosion resistance bar

- Resistant in thermal and earthquake situations

- Excellent ductility and malleability

- Enhanced durability

- Refined grain structure and free from slag and inclusion

- 20% reduction in steel consumption, resulting in significant cost savings

- Yield Strength : 500 MPa (Min) – 72,500 psi

- Ultimate (Tensile) Strength : 625 MPa (Min) – 90,625 psi

- Elongation : 8% min, according to BDS ISO 6935-2:2016

- De-scaled bars offer improved concrete bonding and reduced on-site wastage

- Physical properties and chemical composition are consistent

- Comparatively corrosion resistance bar

- Resistant in thermal and earthquake situations

- Excellent ductility and malleability

- Enhanced durability

- Refined grain structure and free from slag and inclusion

- 20% reduction in steel consumption, resulting in significant cost savings

BAR MARKS & SIZES

To ensure high quality and prevent counterfeit, all ELITE THERMEX rebar products have a unique bar

mark, ELITE THERMEX // B500DWR // Size on the entire length of the bar at metre intervals

WHY CHOOSE ELITE THERMEX?

ELITE THERMEX rebars are specifically designed to meet the rigorous demands of modern construction.

Whether it’s a skyscraper in a bustling city or a resilient structure in an earthquake-prone zone, ELITE

THERMEX offers the reliability and strength required to create infrastructures that last a lifetime.

CONCLUSION

With German Thermex QST Technology at its core, ELITE

THERMEX is not just a product – it’s a promise of excellence,

innovation, and resilience. As the world moves towards

sustainable and robust construction, Elite Steel leads the way

with rebar solutions that combine precision engineering and

superior performance.