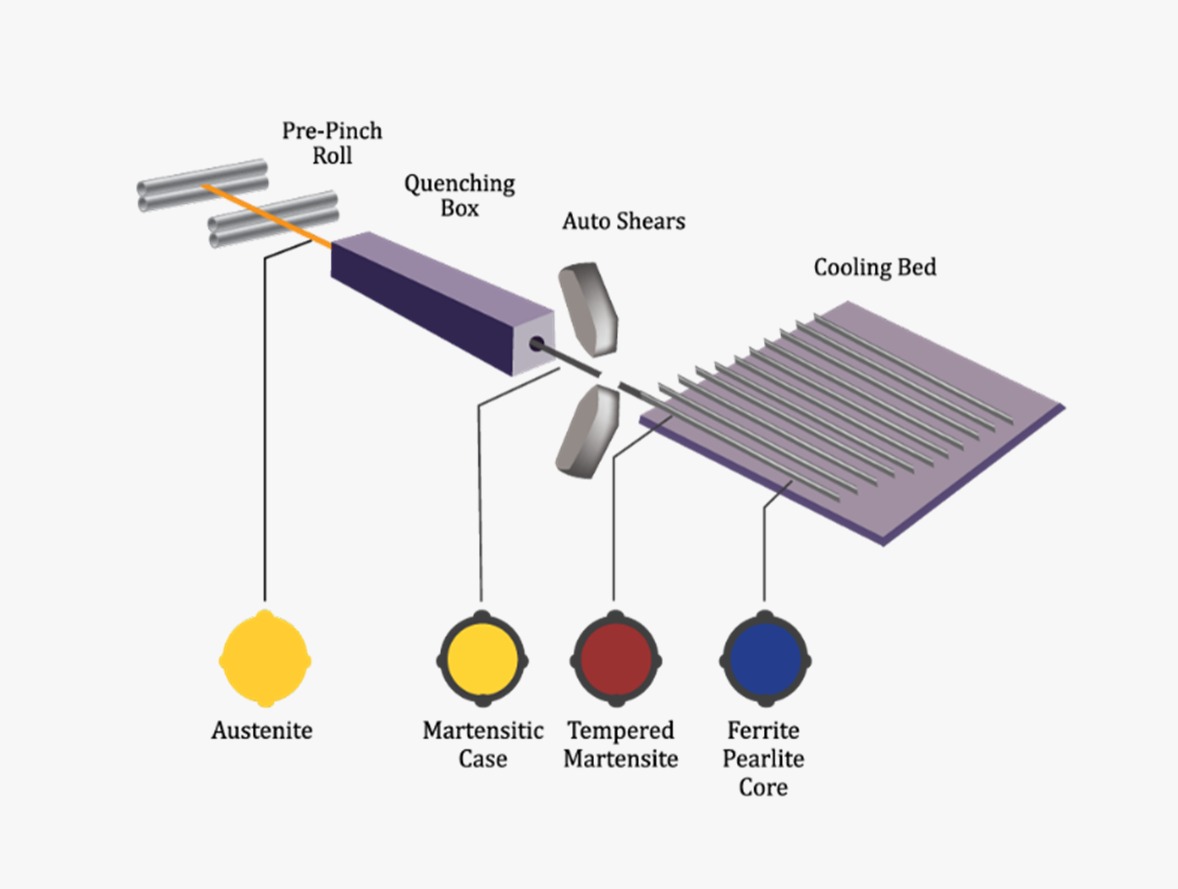

4. Automation and Precision in Rolling Mills: Modern rolling mills in Bangladesh are equipped

with automated control systems like Advanced Quenching Box, Auto Shearing Machine,

Computer Numerical control (CNC) and Universal Testing Machine (UTM) that ensure precise

shaping and sizing of deformed bars. This automation reduces human error, enhances

production efficiency, and results in bars with uniform rib patterns and consistent dimensions.

Such advancements are crucial for maintaining the structural integrity of concrete constructions.

The choice of raw materials significantly influences

the quality of deformed bars. In recent years,

Bangladeshi steel manufacturers have shifted

towards using high-grade billets, which are the

primary raw materials for deformed bar production.

These billets are produced in integrated steel mills in

Bangladesh, ensuring better control over the

chemical composition and mechanical properties of

the final product.

Additionally, innovations in the chemical formula of steel, including the use of low-carbon content and

alloying elements, have enhanced the corrosion resistance and longevity of deformed bars. This is

particularly important in a tropical country like Bangladesh, where humidity and salinity can adversely

affect construction materials

Steel Factory Innovations: The emergence of new technologies and processes at various steel factories

in Bangladesh has positioned the country as a competitive player in the global steel market. The list of

steel mills in Bangladesh continues to expand as demand grows, with each mill striving to innovate and

improve its products. The Bangladesh Steel Manufacturers Association (BSMA) plays a pivotal role

in setting industry standards and promoting best practices among all steel companies in Bangladesh.

This collaborative effort ensures that the industry remains competitive and capable of producing worldclass steel products.

Economic Contributions: With an estimated worth of $62 million as of 2022, the Bangladeshi steel

industry is expected to grow further due to investments in infrastructure projects like roads, bridges, and

buildings—key areas where deformed bars are extensively used.

The choice of raw materials significantly influences

the quality of deformed bars. In recent years,

Bangladeshi steel manufacturers have shifted

towards using high-grade billets, which are the

primary raw materials for deformed bar production.

These billets are produced in integrated steel mills in

Bangladesh, ensuring better control over the

chemical composition and mechanical properties of

the final product.

The choice of raw materials significantly influences

the quality of deformed bars. In recent years,

Bangladeshi steel manufacturers have shifted

towards using high-grade billets, which are the

primary raw materials for deformed bar production.

These billets are produced in integrated steel mills in

Bangladesh, ensuring better control over the

chemical composition and mechanical properties of

the final product.

As we look ahead, continued investment in technology and sustainable practices will be essential for maintaining

competitiveness within both local and international markets. The future of steel industries in Bangladesh looks

promising with these innovations paving the way for more resilient infrastructure development across the nation.